Sintered tabular alumina factory

Sintered tabular alumina production process:

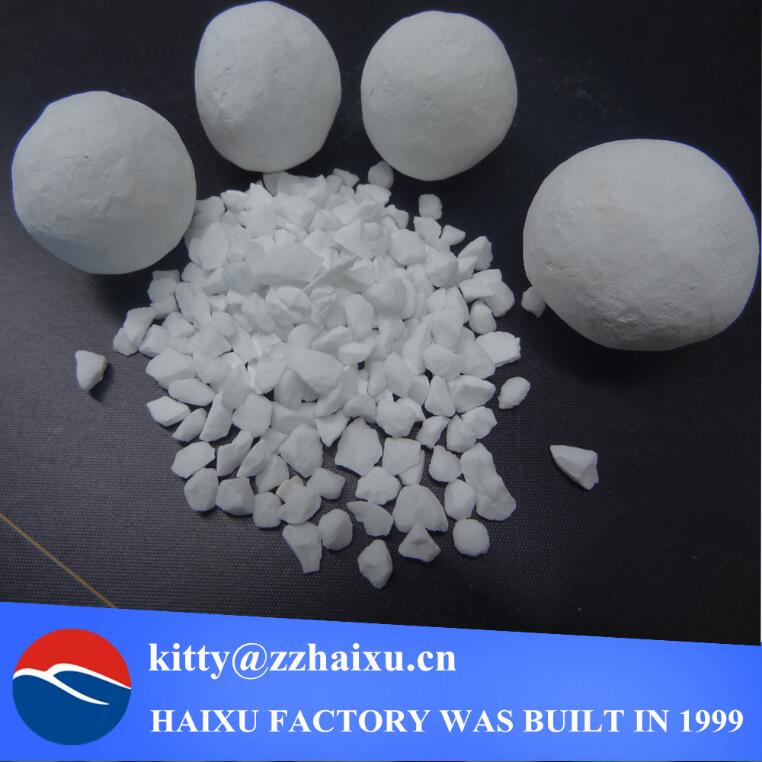

Sintered tabular alumina is a re-crystalline sintered Alpha alumina with high density. It consists of large (50 – 200 µm), flat, tablet-shaped corundum crystals. A feedstock is a calcined alumina ground to a fine powder and palletized to balls with an abt diameter of 25 mm. These balls are sintered (fired) at 1750°C in modern shaft kilns and following, crushed, milled, and sieved to standard fractions/sizes.

Sintered tabular alumina applications

Haixu sintered tabular alumina combines sintered tabular alumina’s standard properties with reduced magnetic iron content along with tight oversize specification. Steps are taken to remove magnetic iron & coarse particles, which can lead to poor product performance. The most common applications are for abrasion and functional filler / epoxy-resin systems. The increased alumina quality can provide greater constancy in the formulation and product properties.

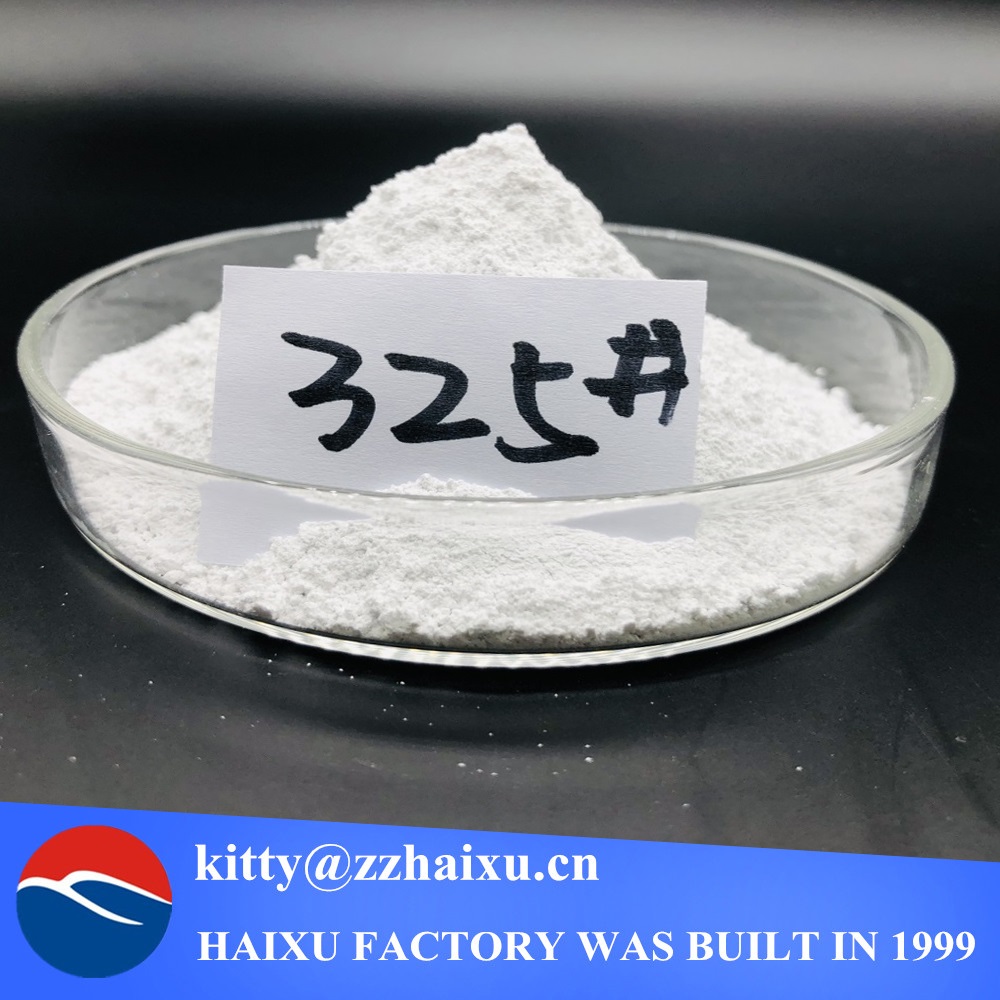

Sintered tabular alumina size:

Grit: -14mesh, -28mesh, -48mesh, 0.5-1mm, 0.2-0.6mm, 0-1mm, 0-0.5mm, 0-0.3mm, 0-0.2mm, 1-3mm, 3-5mm, 3-6mm, 5-8mm

Powder: -100, 200#-0, 325#, -325#, -325 mesh, 0-0.045mm,0-0.075mm

We can make size according to your requirement.