What effect add tabular corundum 0.2-0.6mm in ceramic resistors?

The main functions include improving high temperature stability, enhancing mechanical strength, improving insulation performance and extending service life.

Improved High-Temperature Stability

Tabular corundum has a high melting point (typically ≥1800°C), maintaining material stability in high-temperature environments and preventing structural changes caused by thermal expansion or contraction.

Enhanced Mechanical Strength

Its dense crystal structure and high hardness (Mohs hardness 9) significantly enhance the compressive and flexural strength of resistor components, extending their service life.

Improved Insulation Performance

Tabular corundum has a low dielectric constant (approximately 8-10) and high resistivity (10⁰-10⁰Ω·m), effectively reducing electromagnetic interference and improving the insulation performance of resistor components.

Extended Service Life

Its strong corrosion resistance protects against acid and alkali attack, reducing material degradation caused by environmental factors.

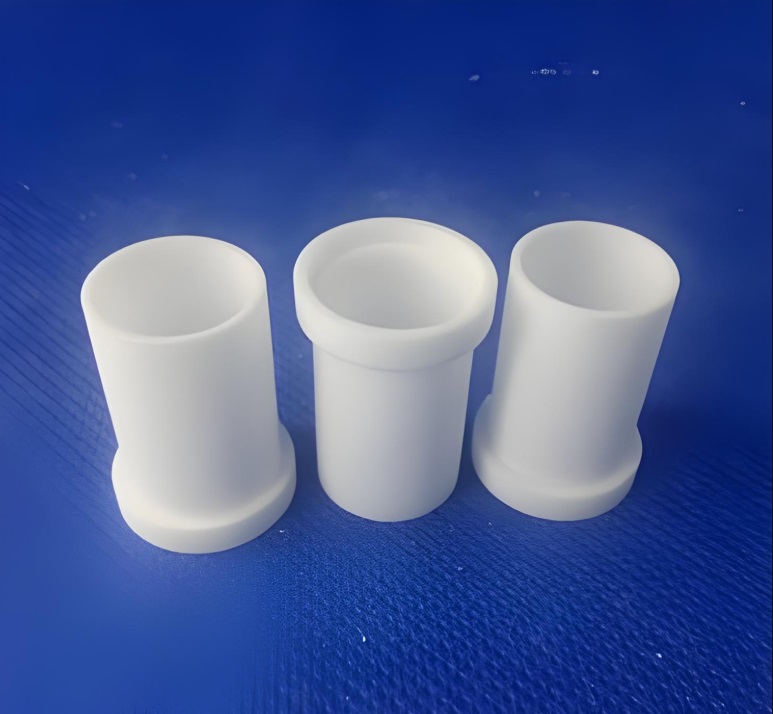

Tabular corundum for refractory has good heat resistance and good bulk temperature thermal shock capabilities. The crystal staggered plate shape, to increasing the mechanical strength of the particles; interior structure full of closed pores, high bulk density, low apparent porosity and water absorption, to reducing the amount of fluid re-use productions; With good physical properties like: high refractoriness, excellent thermal shock resistance, low shrinkage and good thermal load strength etc. Meanwhile, high-purity avoiding damage to machines.

| Style | Chemical Index | Physical Index | |||||

| Al2O3% | SiO2% | Fe2O3% | Na2O% | Volume density (g/cm3) | water absorption | apparent porosity | |

| 0-1mm 0-0.2mm | 99.2min | 0.1max | 0.1max | 0.4max | 3.5 | 1.5 | 5max |

| 200#-0 320#-0 325# | 99.1min | 0.1max | 0.1max | 0.4max | 3.5 | 1.5 | 5max |